Muaj Peev Xwm Loj Hlau CNC M1, M1.5, M2, M2.5, M3 Zawv Zawg Rooj Vag Iav Khib Txuas Ntxiv

Kev Lag Luam Daim Ntawv Thov

1. Cov Kev Ntsuas ntawm Iav Khib

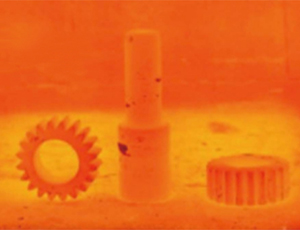

1. Khoom siv: Carbon steel, stainless hlau, txhuas alloy, yas, tooj dag, thiab lwm yam.

2. Module: M1, M1.5, M2, M3, M4, M5, M6, M7, M8 thiab lwm yam.

3. Lub kaum sab xis: 20°.

4. Kev kho qhov chaw: Zinc-plated, Nickel-plated, Black-Oxide, Carburizing, Hardening thiab tempering, nitriding, kev kho mob zaus siab, thiab lwm yam.

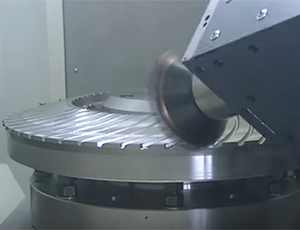

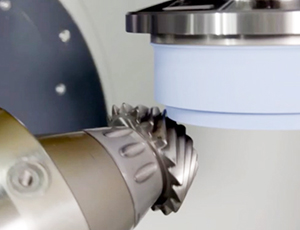

5. Cov Tshuab Tsim Khoom: Gear shaper, hobbing tshuab, CNC tshuab dhos, milling tshuab, drilling tshuab, grinder thiab lwm yam.

6. Kev kho cua sov carburizing thiab quenching.

2. Iav khib hauv Gantry Systems

Hauv lub kaw lus gantry, lub khib iav, tseem hu ua alub kaw lus khib thiab pinion, yog ib qho linear actuator uas muaj ib lub iav ncaj (lub khib) thiab ib lub iav voj voog (lub pinion). Thaum lub pinion tig, nws tsav lub khib kom txav mus rau linearly. Lub tshuab no feem ntau siv rau kev txav mus los linear kom meej thiab rov ua dua, ua rau nws tsim nyog rau kev siv hauv cov kab ke gantry.

Cov yam ntxwv ntawm Gear Rack hauv Gantry Systems:

1,Kev Tawm Tsam Ncaj Qha:

Lub luag haujlwm tseem ceeb ntawm lub khib iav hauv lub kaw lus gantry yog hloov kev txav ntawm lub pinion mus rau hauv kev txav linear ntawm lub khib. Qhov no yog qhov tseem ceeb rau kev txav lub gantry raws txoj kev ncaj.

2,Kev Ntsuas Siab thiab Kev Ntsuas Tseeb:

Cov khib iav tau tsim los muab qhov tseeb thiab qhov tseeb, uas yog qhov tseem ceeb rau cov haujlwm uas xav tau qhov chaw tseeb thiab rov ua dua, xws li CNC machining, 3D printing, thiab cov kab sib dhos tsis siv neeg.

3,Muaj Peev Xwm Thauj Khoom:

Cov khib iav tuaj yeem tuav cov khoom hnyav, ua rau lawv haum rau cov kab ke gantry hnyav siv rau hauv cov ntawv thov kev lag luam.

4,Kev ruaj khov thiab lub zog:

Ua los ntawm cov ntaub ntawv ruaj khov xws li hlau lossis cov hlau sib xyaw ua ke, cov khib iav ruaj khov thiab muaj peev xwm tiv taus cov xwm txheej ua haujlwm hnyav, suav nrog cov khoom thauj siab thiab kev ua haujlwm tas mus li.

5,Kev cuam tshuam qis:

Cov khib iav zoo tau tsim los txo qhov backlash (qhov kev txav me me uas tuaj yeem tshwm sim ntawm cov iav), uas ua rau lub kaw lus raug thiab ruaj khov.

7,Kev Ceev thiab Kev Ua Haujlwm Zoo:

Cov txheej txheem khib iav tuaj yeem ua haujlwm ntawm qhov ceev ceev thiab muab kev sib kis hluav taws xob zoo, ua rau lawv haum rau cov ntawv thov dynamic qhov twg qhov ceev thiab kev teb sai yog qhov tseem ceeb.

8,Kev Txij Nkawm thiab Kev Siv Lubrication:

Kev saib xyuas thiab lubrication kom zoo ntawm cov khib iav yog qhov tsim nyog los xyuas kom meej tias kev ua haujlwm du thiab ntev lub neej ntawm cov khoom.

9,Kev Koom Tes Nrog Lwm Lub Tshuab:

Cov khib iav tuaj yeem yooj yim sib xyaw nrog lwm cov khoom siv kho tshuab xws li cov lus qhia linear, servo motors, thiab encoders los tsim kom muaj lub kaw lus gantry tiav thiab ua haujlwm tau zoo.

10,Kev hloov kho tau:

Cov khib iav tuaj yeem hloov kho raws li qhov siab, ntev, thiab cov khoom siv kom tau raws li cov kev xav tau tshwj xeeb.

Zuag qhia tag nrho, cov iav khib yog qhov tseem ceeb hauv cov kab ke gantry, muab kev txav mus los txhim khu kev qha, meej, thiab ua haujlwm tau zoo rau ntau yam kev siv hauv kev lag luam.

3. Kev Sib Dhos Txuas Ntxiv Rau Iav

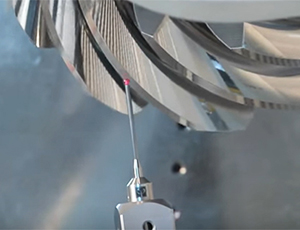

Yuav kom ntseeg tau tias qhov sib dhos ntawm lub khib txuas tau du thiab zoo, nws raug pom zoo kom ntxiv ib nrab hniav rau txhua qhov kawg ntawm lub khib txheem. Qhov no ua rau kev sib txuas ntawm lub khib tom ntej yooj yim dua los ntawm kev cia nws ib nrab hniav txuas rau tag nrho cov hniav. Daim duab hauv qab no qhia txog kev sib txuas ntawm ob lub khib thiab yuav ua li cas lub ntsuas hniav tswj tau qhov chaw suab.

Thaum koom nrog cov khib nyiab helical, cov hniav sib txawv tuaj yeem siv los ua kom tiav qhov kev sib txuas meej.

1. Thaum txuas lub khib, nws raug pom zoo kom xauv cov qhov ntawm ob sab ntawm lub khib ua ntej, thiab tom qab ntawd xauv cov qhov raws li qhov hauv paus. Siv lub ntsuas hniav thaum lub sijhawm sib dhos kom raug thiab ua tiav qhov chaw ntawm lub khib.

2. Thaum kawg, khi cov pins tso rau ntawm ob sab ntawm lub khib kom ua tiav qhov kev sib dhos.

Hoobkas Tsim Khoom

Peb lub tuam txhab muaj thaj chaw tsim khoom ntawm 200,000 square meters, nruab nrog cov khoom siv tsim khoom thiab tshuaj xyuas zoo tshaj plaws los ua kom tau raws li cov neeg siv khoom xav tau. Tsis tas li ntawd, peb nyuam qhuav qhia txog Gleason FT16000 tsib-axis machining center, lub tshuab loj tshaj plaws hauv Suav teb, tsim tshwj xeeb rau kev tsim iav raws li kev koom tes ntawm Gleason thiab Holler.

- Modulus ntau yam: 0.5-42M

- Chav kawm raug: 5-10.

- Qib 5, txog li 1000 hli ntev hauv ib daim

- Qib 6, ntev txog li 2000 hli hauv ib daim.

Peb zoo siab uas peb muaj peev xwm muab kev tsim khoom zoo tshaj plaws, kev ywj pheej thiab kev siv nyiaj tsim nyog rau peb cov neeg siv khoom uas xav tau tsawg. Koj tuaj yeem tso siab rau peb kom xa cov khoom zoo raws li koj cov lus qhia.

Kev Nthuav Dav ntawm Kev Tsim Khoom

Cov Khoom Siv Raw

Txiav Tsis Zoo

Tig

Kev Quenching thiab Tempering

Kev Sib Tsoo Iav

Kev Kho Mob Kub

Kev Sib Tsoo Iav

Kev kuaj xyuas

Kev Tshuaj Xyuas

Peb tau nqis peev rau cov khoom siv kuaj tshiab tshaj plaws, suav nrog Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument thiab Japanese roughness testers thiab lwm yam. Peb cov kws tshaj lij siv cov thev naus laus zis no los ua qhov kev tshuaj xyuas kom raug thiab lav tias txhua yam khoom uas tawm hauv peb lub Hoobkas ua tau raws li cov qauv siab tshaj plaws ntawm kev zoo thiab kev raug. Peb cog lus tias yuav ua kom dhau qhov koj xav tau txhua lub sijhawm.

Cov pob khoom