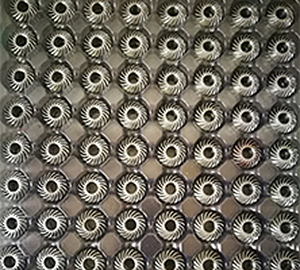

Hypoid Bevel Gears Siv nyob rau hauv Industrial Robot

Cov yam ntxwv tseem ceeb ntawm hypoid iav muaj xws li:

1.High Offset: Lub iav hypoid muaj qhov sib txawv loj ntawm nws cov axes, txhais tau tias cov axes tsis sib tshuam. Qhov no offset tso cai rau ib tug ntau compact thiab saj zawg zog tsim thiab muab kev txhim kho torque hloov peev xwm.

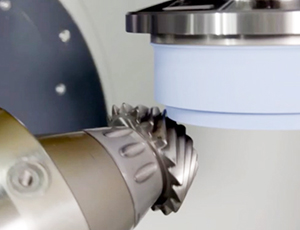

2.Spiral Bevel Gear Hniav Profile: Cov hniav profile ntawm lub iav hypoid zoo ib yam li cov iav bevel iav. Qhov kev tsim no txo qhov kev npliag thiab cuam tshuam ntawm cov hniav thaum lub sijhawm ua haujlwm piv rau lwm hom iav, ua rau kev ua haujlwm zoo dua, ntsiag to.

3 .High Torque Capability: Cov yam ntxwv offset ntawm hypoid gears tuaj yeem ua rau muaj peev xwm ua kom muaj zog ntxiv piv rau lwm hom iav vim nws tso cai rau lub iav loj dua thiab sib cuag ntawm cov hniav. Qhov no ua rau lub zog hypoid haum rau cov ntawv thov uas xav tau kev sib kis siab, xws li tsheb sib txawv.

4. Daim ntawv thov kev siv ntau yam: Hypoid iav tuaj yeem siv rau hauv ntau yam kev siv uas xav tau kev sib cog lus, kev sib kis tau zoo, suav nrog kev sib txawv ntawm tsheb, kev siv tshuab, neeg hlau thiab cov cuab yeej hluav taws xob.

5 . Lubrication Requirements: Hypoid gears feem ntau yuav tsum tau lubrication tshwj xeeb vim yog zawv zawg sib cuag ntawm cov hniav. Gear designs muaj xws li nta xws li cov roj reservoirs thiab grooves los xyuas kom meej lubrication thiab txias ntawm lub iav system.

6 . Txhim kho kev ua haujlwm zoo: Hypoid iav muaj qhov sib kis tau zoo dua thiab kev ua haujlwm zoo piv rau lwm hom iav. Qhov no yog vim qhov ua kom zoo ntawm cov hniav profile thiab thaj chaw sib cuag loj ntawm cov hniav, uas txo cov kev sib txhuam thiab lub zog poob thaum ua haujlwm.

Zuag qhia tag nrho, lub zog hypoid muaj cov qauv tsim tshwj xeeb uas ua rau lawv haum rau ntau yam kev siv, sib txuas ua ke, muaj peev xwm siab zog, ua haujlwm zoo thiab ua haujlwm zoo.

Chaw tsim tshuaj paus

Thawj lub tuam txhab hypoid iav hauv Suav teb tau qhia UMAC thev naus laus zis los ntawm Tebchaws Meskas, tsim keeb kwm thiab hloov pauv cov txheej txheem thev naus laus zis ntawm hypoid iav, txhim kho kev ceev, kev ua haujlwm zoo thiab kev ua haujlwm zoo. Qhov no tau ua rau kev loj hlob ntawm kev lag luam hauv tsev thiab thoob ntiaj teb kev thov rau Tuam Tshoj txoj kev lag luam hypoid iav, tsim Tuam Tshoj txoj haujlwm raws li kev tsim khoom thiab xa tawm hub rau hypoid iav, thaum sib sau ua ke nws cov thawj coj hauv kev tsim cov thev naus laus zis.

Flow of Production

Raw Khoom

Rough Txiav

Tig

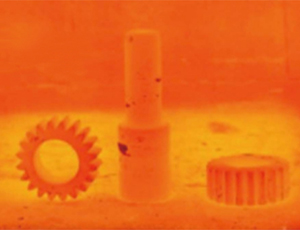

Quenching thiab Tempering

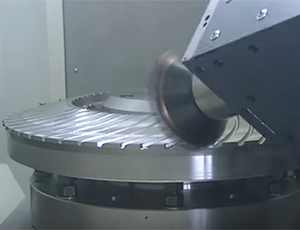

Iav Milling

Kev kho cua sov

Iav sib tsoo

Kev sim

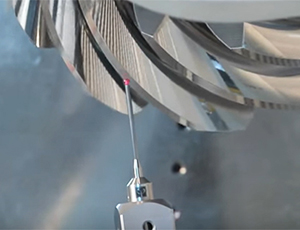

Kev tshuaj xyuas

Peb tau nqis peev nyob rau hauv cov cuab yeej tshiab tshaj plaws, suav nrog Brown & Sharpe ntsuas tshuab, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument thiab Japanese roughness testers thiab lwm yam Peb cov kws tshaj lij siv cov cuab yeej no los ua qhov kev soj ntsuam kom raug thiab lav tias txhua yam khoom uas tawm hauv peb lub Hoobkas ua tau raws li cov qauv siab tshaj plaws ntawm kev ua tau zoo thiab qhov tseeb. Peb cog lus tias yuav ua kom dhau koj qhov kev cia siab txhua lub sijhawm.

Tshaj tawm

Peb yuav muab cov ntaub ntawv zoo meej rau koj qhov kev pom zoo ua ntej xa khoom.

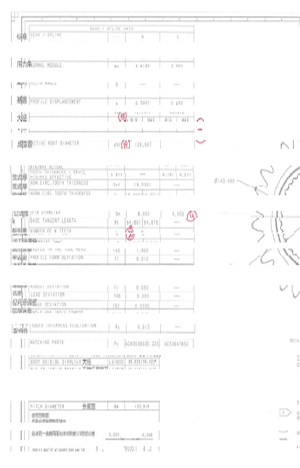

Kev kos duab

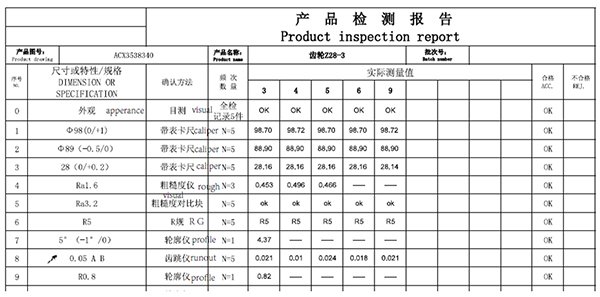

Dimension Report

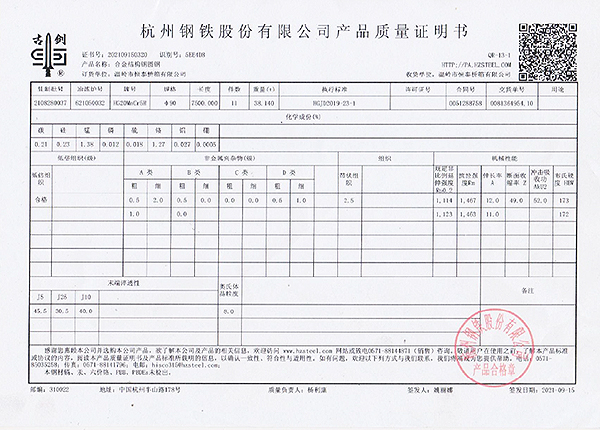

Daim ntawv qhia txog kev kho cua sov

Daim ntawv qhia tseeb

Cov ntaub ntawv qhia

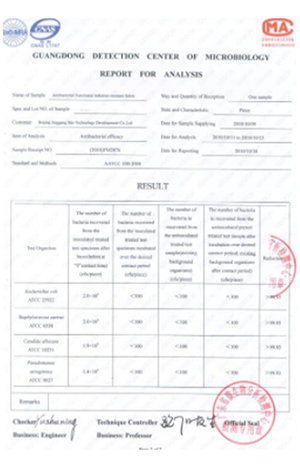

Daim Ntawv Qhia Txog Kev Tshawb Fawb

Pob ntawv

Ntim Pob

Ntim Pob

Thawv

Ntoo pob