Cov Khoom Siv Hluav Taws Xob Zoo Tshaj Plaws rau Kev Sib Kis Fais Fab Zoo

Kev txhais ntawm cov iav miter sib dhos

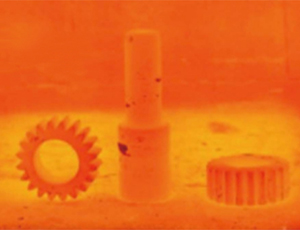

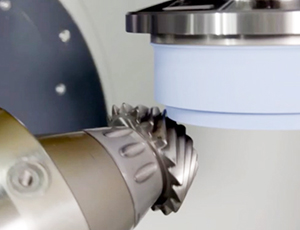

Lub iav miter yog lub iav bevel siv los xa lub zog ntawm ob lub shafts uas sib tshuam. Tsis zoo li cov iav bevel txheem, uas tau tsim los xa lub zog ntawm ob lub shafts hauv tib lub dav hlau, cov iav miter tau tsim tshwj xeeb los xa lub zog ntawm ob lub shafts uas yog perpendicular rau ib leeg. Lawv feem ntau siv rau hauv cov kab ke xa hluav taws xob, tshwj xeeb tshaj yog nyob rau hauv cov ntawv thov uas xav tau cov khoom thauj torque siab thiab kev sib dhos meej.

Feature

1. Muaj Peev Xwm Thauj Khoom Siab:Cov iav Mitered muaj peev xwm xa cov khoom thauj torque siab, ua rau lawv haum rau cov ntawv thov hnyav.

2. Kev Sib Tov Kom Tseeb:Cov iav Mitered yog tsim los tswj kom muaj kev sib phim meej ntawm ob lub shafts uas lawv xa hluav taws xob, uas pab txo qhov hnav thiab ua kom lub neej ntawm lub iav ntev dua.

3. Ua haujlwm ntsiag to:Cov iav txiav helical tsim suab nrov thiab kev co tsawg dua li lwm hom iav vim lawv cov hniav txiav ncaj.

4. Siv tau ntau yam:Cov iav Mitered tuaj yeem siv tau rau ntau yam kev siv, los ntawm cov cuab yeej hluav taws xob thiab cov cuab yeej siv tshuab mus rau robotics, automotive thiab aerospace applications.

Cov hom kev ua tiav uas nquag siv

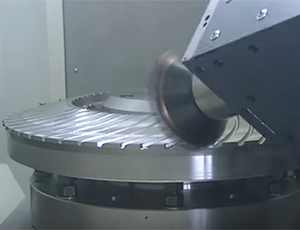

1. Kev Sib Tsoo:Lub tshuab txiav iav tuaj yeem txav mus los ncaj nraim lossis ntsug tawm tsam qhov workpiece los tsim qhov tob thiab qhov profile ntawm cov hniav iav. Cov txheej txheem yog qhov tseeb, thiab cov duab thiab qhov sib nrug ntawm cov hniav raug tswj los ntawm cov duab thiab qhov sib nrug ntawm cov hniav txiav iav. Kev sib tsoo hniav yog siv dav hauv kev tsim cov iav rau ntau yam kev siv, suav nrog tsheb, tshuab kev lag luam, thiab cov khoom siv rau cov neeg siv khoom.

2. Kev Sib Tsoo:Cov txheej txheem ntawm kev ua kom tiav cov hniav ntawm cov iav siv cov log sib tsoo abrasive. Kev sib tsoo ua rau muaj qhov chaw du thiab zoo dua uas txhim kho kev ua haujlwm thiab lub neej ntawm cov iav.

Cov ntawv qhia

Peb muab sijhawm rau peb cov neeg siv khoom los tshuaj xyuas thiab pom zoo txhua daim ntawv zoo ua ntej xa khoom.

1. Kos duab npuas

2. Daim Ntawv Qhia Txog Qhov Loj

3. Daim Ntawv Pov Thawj Khoom Siv

4. Daim Ntawv Qhia Txog Kev Kho Mob Kub

5. Daim Ntawv Qhia Txog Qhov Tseeb

6. Cov Duab thiab Cov Yeeb Yaj Kiab Ib Feem

Hoobkas Tsim Khoom

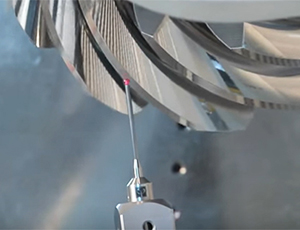

Peb zoo siab los muab ib lub chaw tsim khoom zoo tshaj plaws uas muaj thaj tsam li ntawm 200,000 square meters. Peb lub Hoobkas muaj cov khoom siv tsim khoom thiab tshuaj xyuas tshiab kawg nkaus kom ntseeg tau tias peb tuaj yeem ua tau raws li ntau yam kev xav tau ntawm peb cov neeg siv khoom. Peb txoj kev cog lus rau kev tsim kho tshiab tau pom tseeb hauv peb qhov kev yuav khoom tshiab tshaj plaws - Gleason FT16000 tsib-axis machining center.

- Txhua lub modules

- Txhua tus lej hniav uas xav tau

- Qib siab tshaj plaws ntawm DIN5

- Kev ua haujlwm siab, siab Precision

Peb muaj peev xwm muab kev tsim khoom zoo tshaj plaws, kev ywj pheej thiab kev txuag nyiaj rau cov khoom me me. Ntseeg peb kom xa cov khoom zoo txhua lub sijhawm.

Kev Nthuav Dav ntawm Kev Tsim Khoom

Cov Khoom Siv Raw

Txiav Tsis Zoo

Tig

Kev Quenching thiab Tempering

Kev Sib Tsoo Iav

Kev Kho Mob Kub

Kev Sib Tsoo Iav

Kev kuaj xyuas

Kev Tshuaj Xyuas

Peb tau nqis peev rau cov khoom siv kuaj tshiab tshaj plaws, suav nrog Brown & Sharpe measuring machines, Swedish Hexagon Coordinate Measuring Machine, German Mar High Precision Roughness Contour Integrated Machine, German Zeiss Coordinate Measuring Machine, German Klingberg Gear Measuring Instrument, German Profile Measuring Instrument thiab Japanese roughness testers thiab lwm yam. Peb cov kws tshaj lij siv cov thev naus laus zis no los ua qhov kev tshuaj xyuas kom raug thiab lav tias txhua yam khoom uas tawm hauv peb lub Hoobkas ua tau raws li cov qauv siab tshaj plaws ntawm kev zoo thiab kev raug. Peb cog lus tias yuav ua kom dhau qhov koj xav tau txhua lub sijhawm.

Cov pob khoom

Pob Khoom Sab Hauv

Pob Khoom Sab Hauv

Lub thawv

Pob Khoom Ntoo