Scanning electron microscope tau siv los soj ntsuam qhov qaug zog pob txha thiab txheeb xyuas cov txheej txheem tawg; Nyob rau tib lub sijhawm, spin dabtsi yog khoov qaug zog kuaj tau ua tiav ntawm cov qauv decarburized ntawm qhov kub sib txawv los sib piv lub neej qaug zog ntawm kev sim steel nrog thiab tsis muaj decarburization, thiab txheeb xyuas cov txiaj ntsig ntawm decarburization ntawm kev qaug zog ntawm kev sim steel. Cov txiaj ntsig tau pom tias, vim muaj kev sib xyaw ua ke ntawm oxidation thiab decarburization nyob rau hauv cov txheej txheem cua sov, kev sib cuam tshuam ntawm ob, uas ua rau lub thickness ntawm tag nrho decarburized txheej nrog kev loj hlob ntawm qhov kub thiab txias qhia tau hais tias ib tug qauv ntawm kev nce thiab tom qab ntawd txo qis, thickness ntawm tag nrho decarburized txheej ncav cuag tus nqi siab tshaj plaws ntawm 120 μm ntawm 750 ℃, thiab lub thickness ntawm tag nrho decarburized txheej ncav cuag tus nqi tsawg kawg nkaus ntawm 20 μm ntawm 850 ℃, thiab qaug zog txwv ntawm cov hlau xeem yog li 760 MPa, thiab lub hauv paus ntawm qaug zog tawg nyob rau hauv lub xeem steel yog tsuas yog Al2O3 non-metallic inclusions; decarburization tus cwj pwm zoo heev txo qhov qaug zog lub neej ntawm kev sim steel, cuam tshuam rau kev qaug zog ntawm kev sim steel, lub thicker txheej decarburization, lub neej qaug zog qis dua. Txhawm rau txo qhov cuam tshuam ntawm decarburization txheej ntawm kev qaug zog ntawm kev sim steel, qhov zoo tshaj plaws kev kho cua sov ntawm cov hlau xeem yuav tsum tau teem rau ntawm 850 ℃.

Iav yog ib qho tseem ceeb ntawm lub tsheb, vim kev ua haujlwm ntawm kev kub ceev, qhov meshing ib feem ntawm lub iav nto yuav tsum muaj lub zog siab thiab kev puas tsuaj, thiab cov hauv paus hniav yuav tsum muaj kev ua haujlwm zoo bending qaug zog vim qhov rov ua haujlwm tas li, txhawm rau kom tsis txhob muaj cov kab nrib pleb uas ua rau cov khoom siv. tawg. Kev tshawb fawb qhia tau hais tias decarburization yog ib qho tseem ceeb cuam tshuam rau lub spin dabtsi yog khoov qaug zog kev ua tau zoo ntawm cov ntaub ntawv hlau, thiab spin dabtsi yog khoov qaug zog kev ua tau zoo yog ib qho tseem ceeb qhia txog cov khoom zoo, yog li nws yog tsim nyog los kawm txog tus cwj pwm decarburization thiab spin dabtsi yog khoov qaug zog ntawm cov khoom xeem.

Nyob rau hauv daim ntawv no, cov cua sov kho rauv ntawm 20CrMnTi iav steel nto decarburization xeem, txheeb xyuas cov cua kub sib txawv ntawm qhov ntsuas steel decarburization txheej tob ntawm txoj cai hloov; siv QBWP-6000J yooj yim beam qaug zog kuaj tshuab ntawm qhov ntsuas steel teb bending qaug zog kuaj, kev txiav txim siab ntawm kev sim steel qaug zog kev ua tau zoo, thiab tib lub sijhawm los tshuaj xyuas qhov cuam tshuam ntawm decarburization ntawm kev qaug zog ntawm kev sim steel rau qhov tseeb ntau lawm los txhim kho. cov txheej txheem ntau lawm, txhim khu cov khoom zoo thiab muab cov ntaub ntawv tsim nyog. Qhov kev sim steel qaug zog kev ua tau zoo yog txiav txim siab los ntawm lub tshuab spin bending fatigue test.

1. Cov ntaub ntawv xeem thiab cov txheej txheem

Cov khoom siv kuaj rau ib chav tsev muab 20CrMnTi iav hlau, cov tshuaj lom neeg tseem ceeb raws li qhia hauv Table 1. Decarburization test: cov khoom siv kuaj tau ua tiav rau hauv Ф8 mm × 12 mm cylindrical specimen, saum npoo yuav tsum ci tsis muaj stains. Thaum tshav kub kub kho rauv tau rhuab mus rau 675 ℃ , 700 ℃ , 725 ℃ , 750 ℃ , 800 ℃ , 850 ℃ , 900 ℃ , 950 ℃ , 1,000 ℃ , rau hauv cov qauv thiab tuav 1 h, thiab ces cua txias rau chav tsev kub. Tom qab kev kho cua sov ntawm cov qauv los ntawm kev teeb tsa, kev sib tsoo thiab polishing, nrog 4% ntawm nitric acid cawv tov, siv metallurgical microscopy los soj ntsuam cov txheej txheem steel decarburization, ntsuas qhov tob ntawm decarburization txheej ntawm qhov kub sib txawv. Spin bending fatigue test: cov khoom siv ntsuas raws li qhov yuav tsum tau ua ntawm ob pawg ntawm spin bending fatigue specimens, thawj pab pawg tsis ua decarburization test, pawg thib ob ntawm decarburization test ntawm qhov sib txawv. Siv lub spin bending fatigue testing tshuab, ob pab pawg ntawm kev sim steel rau spin dabtsi yog khoov qaug zog kuaj, kev txiav txim siab ntawm kev qaug zog ntawm ob pawg ntawm kev sim steel, kev sib piv ntawm kev qaug zog lub neej ntawm ob pawg ntawm kev sim steel, kev siv cov scanning. electron microscope qaug zog fracture soj ntsuam, txheeb xyuas cov laj thawj ntawm kev puas tsuaj ntawm cov qauv, txhawm rau tshawb xyuas cov txiaj ntsig ntawm decarburization ntawm lub zog qaug zog ntawm cov hlau kuaj.

Table 1 Tshuaj muaj pes tsawg leeg (mas feem) ntawm cov hlau xeem wt%

Cov nyhuv ntawm cov cua kub kub ntawm decarburization

Lub morphology ntawm decarburization lub koom haum nyob rau hauv txawv cua kub kub yog qhia nyob rau hauv daim duab 1. Raws li tau pom los ntawm daim duab, thaum lub kub yog 675 ℃, tus qauv nto tsis tshwm decarburization txheej; Thaum qhov kub nce mus txog 700 ℃, cov qauv decarburization txheej pib tshwm, rau nyias ferrite decarburization txheej; nrog rau qhov kub thiab txias nce mus rau 725 ℃, cov qauv decarburization txheej thickness nce ho; 750 ℃ decarburization txheej thickness ncav cuag nws qhov siab tshaj plaws tus nqi, lub sij hawm no, cov ferrite lis ntau meej, ntxhib; Thaum qhov kub nce mus txog 800 ℃, decarburization txheej thickness pib txo qis, nws thickness poob mus rau ib nrab ntawm 750 ℃; Thaum qhov kub thiab txias tseem nce mus txog 850 ℃ thiab lub thickness ntawm decarburization yog qhia nyob rau hauv daim duab 1. 800 ℃, tag nrho decarburization txheej thickness pib txo qis, nws thickness poob mus rau 750 ℃ thaum ib nrab; Thaum qhov kub thiab txias tseem nce mus txog 850 ℃ thiab siab dua, qhov ntsuas steel tag nrho decarburization txheej thickness tseem txo qis, ib nrab decarburization txheej thickness pib maj mam nce mus txog rau tag nrho decarburization txheej morphology tag nrho ploj, ib nrab decarburization txheej morphology maj mam meej. Nws tuaj yeem pom tias lub thickness ntawm tag nrho decarburized txheej nrog qhov nce hauv qhov kub thiab txias tau nce ntxiv thiab tom qab ntawd txo qis, vim li cas qhov tshwm sim no yog vim cov qauv hauv cov txheej txheem cua sov tib lub sij hawm oxidation thiab decarburization tus cwj pwm, tsuas yog thaum lub sij hawm oxidation. tus nqi decarburization yog ceev tshaj qhov ceev ntawm oxidation yuav tshwm sim decarburization. Thaum pib ntawm cua sov, lub thickness ntawm tag nrho decarburized txheej yuav maj mam nce nrog rau qhov kub thiab txias kom txog rau thaum lub thickness ntawm tag nrho cov decarburized txheej mus txog qhov siab tshaj plaws tus nqi, nyob rau lub sij hawm no mus txuas ntxiv nce qhov kub thiab txias, tus nqi oxidation yog sai dua. tus nqi decarburization, uas inhibits qhov nce ntawm tag nrho decarburized txheej, uas ua rau ib tug downward trend. Nws tuaj yeem pom tau tias, nyob rau hauv thaj tsam ntawm 675 ~ 950 ℃, tus nqi ntawm lub thickness ntawm tag nrho decarburized txheej ntawm 750 ℃ yog qhov loj tshaj plaws, thiab tus nqi ntawm cov thickness ntawm tag nrho decarburized txheej ntawm 850 ℃ yog qhov tsawg tshaj plaws, Yog li ntawd, qhov ntsuas kub ntawm cov hlau kuaj tau pom zoo kom yog 850 ℃.

Fig.1 Histomorphology ntawm decarburized txheej ntawm kev sim steel tuav ntawm cov cua kub sib txawv rau 1h

Piv nrog rau txheej semi-decarburized, lub thickness ntawm tag nrho decarburized txheej muaj qhov cuam tshuam tsis zoo rau cov khoom siv, nws yuav txo tau cov khoom siv zoo heev, xws li txo lub zog, hardness, hnav tsis kam thiab qaug zog txwv. , thiab lwm yam, thiab tseem ua rau kom muaj kev cuam tshuam rau cov kab nrib pleb, cuam tshuam qhov zoo ntawm vuam thiab lwm yam. Yog li ntawd, tswj lub thickness ntawm tag nrho decarburized txheej yog qhov tseem ceeb heev los txhim kho cov khoom ua tau zoo. Daim duab 2 qhia txog qhov sib txawv ntawm qhov sib txawv ntawm cov tuab ntawm cov txheej txheem decarburized tag nrho nrog qhov kub thiab txias, uas qhia tau hais tias qhov sib txawv ntawm cov tuab ntawm cov txheej txheem decarburized tag nrho kom meej meej. Nws tuaj yeem pom los ntawm daim duab uas lub thickness ntawm tag nrho decarburized txheej tsuas yog hais txog 34μm ntawm 700 ℃; Nrog rau qhov kub thiab txias nce mus txog 725 ℃, lub thickness ntawm tag nrho decarburized txheej nce ho mus rau 86 μm, uas yog ntau tshaj ob npaug ntawm cov thickness ntawm tag nrho decarburized txheej ntawm 700 ℃; Thaum qhov kub thiab txias tau nce mus rau 750 ℃, lub thickness ntawm tag nrho decarburized txheej Thaum kub nce mus txog 750 ℃, lub thickness ntawm tag nrho decarburized txheej ncav cuag tus nqi siab tshaj ntawm 120 μm; Raws li qhov kub thiab txias tseem nce ntxiv, lub thickness ntawm tag nrho decarburized txheej pib txo qis, mus rau 70 μm ntawm 800 ℃, thiab tom qab ntawd mus rau qhov tsawg kawg nkaus tus nqi ntawm 20μm ntawm 850 ℃.

Fig.2 Thickness ntawm tag nrho decarburized txheej ntawm qhov sib txawv kub

Kev cuam tshuam ntawm decarburization ntawm kev qaug zog kev ua haujlwm hauv spin dabtsi yog khoov

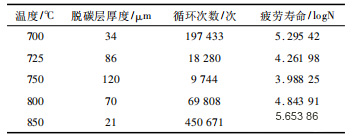

Txhawm rau kawm txog cov txiaj ntsig ntawm decarburization ntawm lub zog qaug zog ntawm lub caij nplooj ntoo hlav steel, ob pawg ntawm kev sib tw spinning qaug zog tau ua tiav, thawj pab pawg yog kev sim qaug zog ncaj qha yam tsis muaj decarburization, thiab pawg thib ob yog kev sim qaug zog tom qab decarburization ntawm tib qhov kev ntxhov siab. qib (810 MPa), thiab cov txheej txheem decarburization tau tuav ntawm 700-850 ℃ rau 1 h. Thawj pawg ntawm cov qauv yog qhia nyob rau hauv Table 2, uas yog lub neej qaug zog ntawm lub caij nplooj ntoos hlav steel.

Lub neej qaug zog ntawm thawj pab pawg ntawm cov qauv yog qhia hauv Table 2. Raws li tuaj yeem pom los ntawm Table 2, tsis muaj decarburization, qhov kev sim steel tsuas yog raug rau 107 cycles ntawm 810 MPa, thiab tsis muaj kev puas tsuaj; thaum qhov kev ntxhov siab tshaj 830 MPa, qee qhov qauv pib tawg; Thaum qhov kev ntxhov siab tshaj 850 MPa, cov qauv qaug zog tau tawg tag nrho.

Table 2 Kev qaug zog lub neej nyob rau hauv ntau theem kev ntxhov siab (tsis muaj decarburization)

Txhawm rau txiav txim siab qhov qaug zog, cov txheej txheem pab pawg yog siv los txiav txim siab qaug zog ntawm cov hlau xeem, thiab tom qab kev txheeb xyuas cov ntaub ntawv, qhov kev qaug zog ntawm cov hlau xeem yog li 760 MPa; txhawm rau ua kom lub neej qaug zog ntawm kev sim steel nyob rau hauv cov kev ntxhov siab sib txawv, SN nkhaus yog npaj, raws li qhia hauv daim duab 3. Raws li pom tau los ntawm daim duab 3, cov kev ntxhov siab sib txawv sib txawv ntawm lub neej qaug zog, thaum lub neej qaug zog ntawm 7. , sib raug rau tus naj npawb ntawm cov voj voog rau 107, uas txhais tau hais tias cov qauv hauv qab no yog dhau los ntawm lub xeev, tus nqi sib xws tuaj yeem kwv yees raws li tus nqi qaug zog, uas yog, 760 MPa. Nws tuaj yeem pom tau tias S - N nkhaus yog qhov tseem ceeb rau kev txiav txim siab ntawm kev qaug zog lub neej ntawm cov khoom muaj qhov tseem ceeb siv tus nqi.

Daim duab 3 SN nkhaus ntawm kev sim steel teb bending qaug zog test

Lub neej qaug zog ntawm pawg thib ob ntawm cov qauv yog qhia hauv Table 3. Raws li tuaj yeem pom los ntawm Table 3, tom qab qhov kev sim steel yog decarburized ntawm qhov kub sib txawv, tus naj npawb ntawm cov voj voog yog pom tseeb txo, thiab lawv muaj ntau dua 107, thiab tag nrho. cov qauv qaug zog yog tawg, thiab lub neej qaug zog txo qis heev. Ua ke nrog cov saum toj no decarburized txheej thickness nrog qhov kub thiab txias hloov nkhaus tuaj yeem pom, 750 ℃ decarburized txheej thickness yog qhov loj tshaj plaws, sib xws rau tus nqi qis tshaj ntawm lub neej qaug zog. 850 ℃ decarburized txheej thickness yog qhov tsawg tshaj plaws, sib haum rau lub neej qaug zog tus nqi kuj siab. Nws tuaj yeem pom tias tus cwj pwm decarburization zoo heev txo qhov qaug zog ntawm cov khoom siv, thiab cov txheej decarburized thicker, lub neej qaug zog qis dua.

Table 3 Lub neej qaug zog ntawm qhov sib txawv decarburization kub (560 MPa)

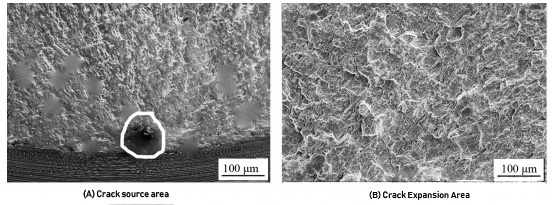

Qhov qaug zog tawg morphology ntawm tus qauv tau pom los ntawm kev siv lub tshuab ntsuas hluav taws xob, raws li qhia hauv daim duab 4. Daim duab 4(a) rau qhov chaw tawg, daim duab tuaj yeem pom pom tseeb qaug zog arc, raws li qhov qaug zog arc mus nrhiav qhov chaw. ntawm qaug zog, tuaj yeem pom, qhov tawg ntawm qhov "ntses-qhov muag" tsis yog xim hlau inclusions, inclusions ntawm qhov yooj yim ua rau kev ntxhov siab concentration, ua rau qaug zog tawg; Fig. 4(b) rau qhov tawg extension cheeb tsam morphology, yuav pom pom tseeb qaug zog kab txaij, yog dej-zoo li tis, belongs rau quasi-dissociative puas, nrog tawg expanding, nws thiaj li ua rau puas. Daim duab 4(b) qhia tau hais tias lub morphology ntawm tawg expansion cheeb tsam, pom tseeb qaug zog streaks yuav pom, nyob rau hauv daim ntawv ntawm cov dej-zoo li faib, uas belongs rau quasi-dissociative puas, thiab nrog rau kev nthuav dav ntawm cov kab nrib pleb, thaum kawg ua rau tawg. .

Fatigue fracture analysis

Fig.4 SEM morphology ntawm qaug zog tawg nto ntawm kev sim steel

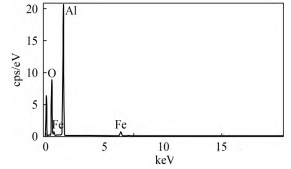

Txhawm rau txiav txim siab txog hom kev suav nrog hauv daim duab 4, lub zog spectrum muaj pes tsawg leeg tsom xam tau ua tiav, thiab cov txiaj ntsig tau qhia hauv daim duab 5. Nws tuaj yeem pom tias cov khoom tsis yog xim hlau suav nrog feem ntau yog Al2O3 inclusions, qhia tias cov inclusions. yog lub hauv paus tseem ceeb ntawm cov kab nrib pleb tshwm sim los ntawm inclusions cracking.

Daim duab 5 Zog Spectroscopy ntawm Non-metallic Inclusions

Xaus

(1) Tso cov cua kub kub ntawm 850 ℃ yuav txo qhov tuab ntawm cov txheej decarburized kom txo tau cov nyhuv ntawm kev qaug zog.

(2) Kev qaug zog txwv ntawm qhov ntsuas steel spin dabtsi yog khoov yog 760 MPa.

(3) Kev ntsuas steel tawg hauv cov khoom tsis yog xim hlau, feem ntau yog Al2O3 sib tov.

(4) decarburization tiag txo cov qaug zog lub neej ntawm cov hlau xeem, lub thicker lub decarburization txheej, qhov qis lub neej qaug zog.

Post lub sij hawm: Jun-21-2024